The composite magnetic system is composed of NdFeB, a special permanent magnet with high coercivity and high remanence. The utility model has the advantages of maintenance-free, strong magnetic force, long service life, simple installation, convenient use and reliable operation. It is suitable for removing iron from non-magnetic materials on belt conveyor, vibration conveyor, electromagnetic vibration feeder, plate iron remover and discharge chute. Removal of 0.1-35 kg of ferromagnetic material, internal permanent magnet system service life of more than 10 years. When more ferromagnets are adsorbed by permanent magnets, the non-magnetic scraper is used to remove them artificially or gloves are worn to remove them.

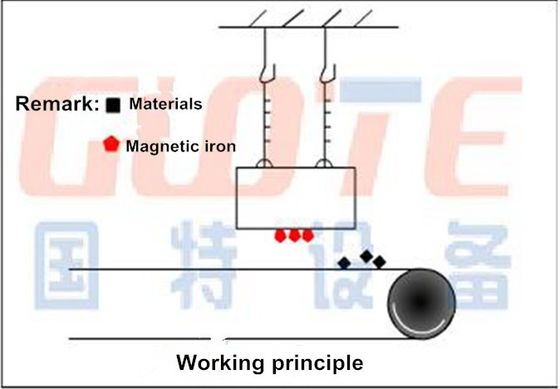

Working Principle

When the granular material passes under the permanent magnet self-unloading iron remover, the ferromagnetic impurities mixed in the material are absorbed about 0.1-0.36 kg. Because the belt on the iron remover keeps running, when the ferromagnetic material adsorbed on the belt passes through the non-magnetic area, it is scraped out by the iron parts on the belt and thrown into the iron collecting box, thus achieving the goal of continuous automatic iron removal.

It is suitable for coal ports, large-scale thermal power plants, coal mines, building materials and other places with high requirements for iron removal. It can work normally in such harsh environments as dust, humidity and severe salt spray corrosion at the seaside. The product quality is stable, mature and reliable.

Specifications

1. Includes controller and suspension bolts.

2. Durable mechanical design for outdoor use.

Technical characteristics

1. With high coercivity and high remanence of permanent magnet NdFeB composite magnetic system, strong magnetic field, large suction.

2. The installation is simple, the use is convenient, the operation is reliable, maintenance free.

3. All technical indicators are in line with JB/T8711-2006.

TECH INTRO

1. High-performance NdFeB as magnetic source has strong magnetism and is not easy to demagnetize.

2. The control part can be interlocked by belt conveyor, which can realize manual control and centralized control in situ.

3. No need for rectifier control device, high reliability.

4. When the power is cut off, the iron sucked on the iron remover will not fall back on the conveying material.

5. There are no insulation and voltage withstanding problems. A discarded iron conveyor belt driven by an explosion-proof motor can be used as an explosion-proof dust collector. However, the magnetic field intensity of permanent magnet iron remover will be attenuated, and attention should be paid to investigation and implementation when selecting.

Parameter

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!